What You Need to Know about Heavy Duty Equipment

The heavy equipment industry has continued to have tremendous growth over the years.

Heavy equipment emerged after the end of World War II, and that came with an increase in people who began to move to more suburban areas outside of major cities. Eventually, this led to the establishment of major roads and highways, which allowed for the easy movement of this heavy machinery equipment on the roads, as well as population growth.

With the continuous advancement of technology, heavy machinery has evolved considerably. Below, you’ll learn a little bit more about heavy duty equipment and the variety of equipment out there.

Types of Equipment

There is a huge variety of heavy machinery and equipment available, each with their own function and applications..

As with anything, there are usually multiple model and brand options for each piece of equipment. The basic function will be the same, but there can be significant variants in speed, size, capacity and technology. Also, the overall quality of the product and its lifespan can vary considerably.

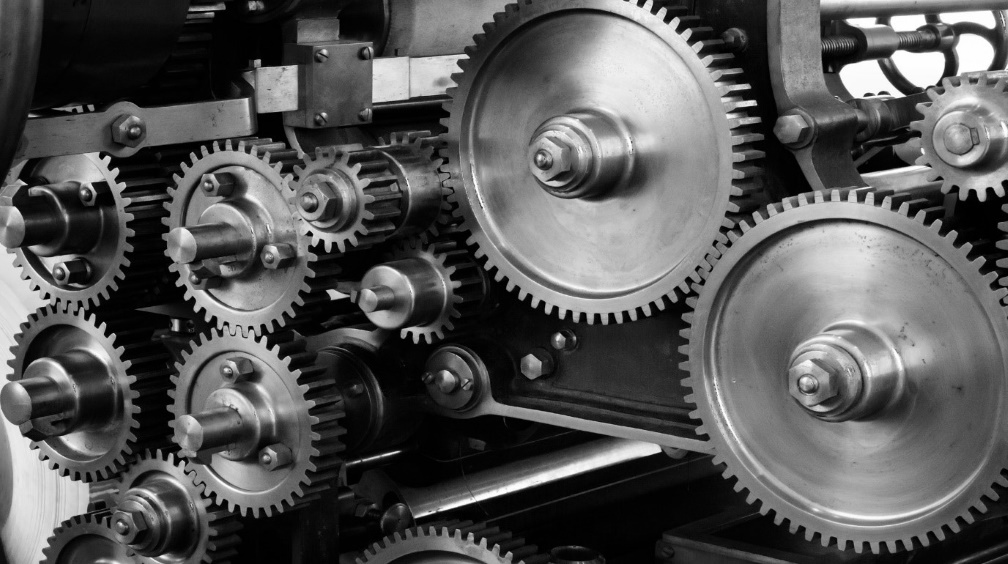

Each item of equipment comprises a multitude of parts, from the chassis, to the wheels or rollers, to the engine and heavy-duty gearbox. And each part contains tens, if not hundreds or thousands, of materials and components.

For example, an industrial gearbox is a mechanical device which is used to change the speed or increase the output torque of a motor. It forms just one part of the overall item of equipment, however in itself it comprises several key components, including a clutch shaft, a counter shaft, a main shaft, bearings gears and a gear selector fork.

As a general rule, a higher quality piece of equipment will comprise higher quality components and will have a longer lifespan than a lower-grade alternative. Higher quality, longer-lasting components will usually mean less downtime, as fewer replacements and repairs are required.

This is something to factor in when purchasing your equipment; a cheaper up-front option might not work out cheaper in the long-run.

However, if you're looking to purchase such a piece of equipment, your choice will obviously depend on the work and goals you aim to achieve.

But let's look at some of the main types of heavy machinery and discuss some of the key safety elements you need to be aware of:

Lifting Equipment

If you need a machine for hoisting and lifting, you’ll need a forklift. The machine has a high-powered truck you can use to lift up to 50 tonnes. Forklifts are popular in warehouses where large palettes need moving on a regular basis.

Another popular piece of lifting equipment is a crane. Cranes are often used on construction sites and can reach heights of over 100 metres. The tallest crane in the world can achieve a maximum height of 248 metres.

Excavation

excavators are used to excavate sites, or dig large holes. The machine has a 360-degree bucket arm that allows for easy maneuverability. The machine can handle heavy loads and is used for the excavation of large sites,, rough grading and mining, among other functions.

Backhoe Loaders

Backhoe loaders perform a similar task to excavators, however they are smaller and lighter. They are fitted with a controllable shovel on the front and a container at the back. These machines can perform a wide range of tasks, including digging holes, landscaping, the transportation of certain building materials and small demolitions.

Bulldozers

Bulldozers are high-powered pieces of equipment used to move huge mounds of earth, rocks or building debris. Their powerful caterpillar tracks and broad curved blade at the front allow them to move effectively along the ground, clearing a path in their wake.

Safety Training

Heavy-duty equipment is extremely powerful. If you're operating this type of machinery, you need to be fully-trained and up-to-date regarding the latest safety requirements and features. Training will include both class work and practical guidance. You will learn how to identify hazards and how to maneuver safely.

Inspections

Knowledge and experience of using heavy-duty equipment means you should know the key things to look out for before operating your machinery – and you should know when things don’t seem right.

While it’s important as an operator to know your machinery and perform regular inspections, regular maintenance and servicing by a professional is required.

A professional service involves an in-depth inspection of your equipment – and repair work where required.

Regular servicing and maintenance is not only critical from a safety perspective, but it can also save you money in the long-run. Addressing smaller issues can prevent them from escalating into bigger issues which are more costly to fix and require more downtime.