ROBOTICS SUCCESS STORY ATTRACTS ENTHUSIASTIC AUSTRALASIAN INVESTORS

The latest investment offering for inspection industry disruptor INVERT ROBOTICS has closed after attracting considerable interest from a number of high net worth and institutional investors from across Australia and New Zealand.

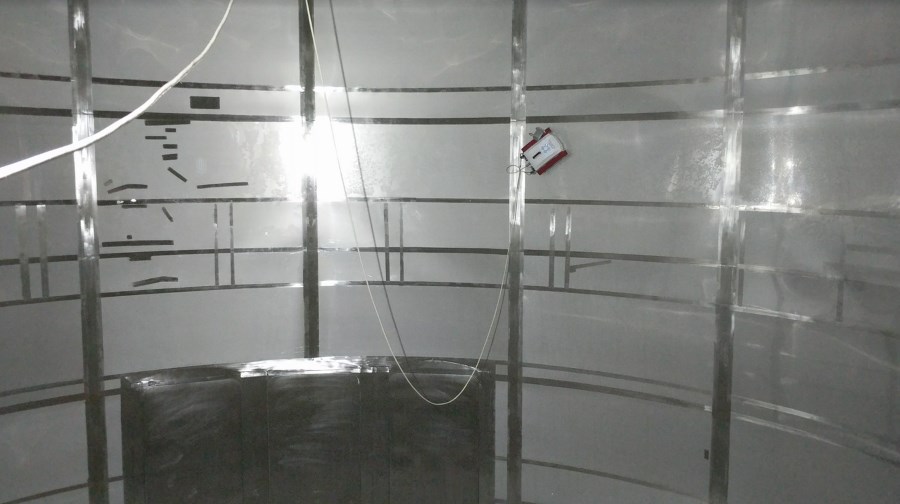

INVERT ROBOTICS provides non-destructive inspection services using state of the art mobile climbing robots. INVERT ROBOTICS’ climbing robots enable precise and accurate remote inspection of non-ferromagnetic surfaces such as stainless steel, carbon fibre, aluminium and glass. INVERT ROBOTICS’ patented robots are installed with high definition cameras and sensor technology to allow for equipment to be assessed for maintenance and for preventative analysis on a remote basis. Inspectors are fed real-time video during the inspection that allows for immediate and highly accurate analysis.

The device is already being used by the major Australian and New Zealand dairy companies and co-operatives such as Fonterra, Synlait and Murray Goldburn, as well as a number of global food and beverage brands. It is also attracting interest across other sectors and throughout the food and beverage manufacturing industry in Europe and Asia such as FrieslandCampina and Heineken.

The Company has also captured the attention of those working in the lucrative aviation inspection market and is poised to make a European partnership announcement soon regarding its successful development of further advanced robot technology. The company is also looking at potential opportunities in the chemical industry, in addition to further work with energy, oil and gas companies.

Following an almost million dollar crowdfunding campaign through the Sydney-based platform Equitise, a further NZ$6.4 million has now been raised from a limited sophisticated private investor round. Shareholders now include the former CEO of Macquarie Group Ltd, Allan Moss, and Inception Fiduciary Pty Ltd.

These investments add to the considerable funding received from government and private venture capital sources soon after the company was founded by its now Chief Technical Officer, James Robertson.

Since 2015/2016, INVERT ROBOTICS has experienced exponential growth; for the 2018/19 Financial Year, its revenue is expected to further quadruple, with significant contributions from European operations.

“Unlike other inspection methods using dyes, drones and optical or laser devices, INVERT ROBOTICS’s technology provides 360-degree diagnostics and does so in up to half the time of traditional inspections”, said INVERT ROBOTICS’ Managing Director Neil Fletcher.

“The accuracy, efficiency and the value-adding environmental and safety benefits of robotic technology makes it an obvious choice as global consumer demand for product safety, brand integrity and transparency grows,” Fletcher said.

Given the company’s rapid growth, in addition to its Australasian base in Christchurch, INVERT ROBOTICS have opened an office in the Netherlands and is poised to open premises to operate in Germany and Denmark.

About INVERT ROBOTICS

INVERT ROBOTICS designs and develops robotic non-destructive testing (NDT) technologies used for the inspection of non-ferromagnetic surfaces in the food and beverage, dairy, aviation, pharmaceutical, and oil and gas industries. Undertaking these audit services enables companies to then take action, greatly assisting in food security and overall consumer and passenger safety. With its beginnings at the University of Canterbury’s School of Engineering in Christchurch, New Zealand, the company quickly attracted government and private investment, utilising robots for 360 degree inspection technology, rapidly growing into an industry ‘disruptor’. Sought out by major consumer and industry brands in Australasia, Europe and Asia, Invert Robotics have worked for six of the top eight global dairy companies with the world’s quickest and safest inspection technology available.

More at www.invertrobotics.com