Understanding Electrical Thermal Imaging and Switchboard Thermal Imaging for Safer Systems

Electrical systems are the backbone of residential, commercial, and industrial spaces. Despite their importance, many electrical faults remain hidden until they become critical. This is where electrical thermal imaging and switchboard thermal imaging come into play. These non-invasive techniques provide a visual representation of heat distribution, allowing professionals to identify hot spots and prevent potential hazards before they cause damage or downtime.

What is Electrical Thermal Imaging?

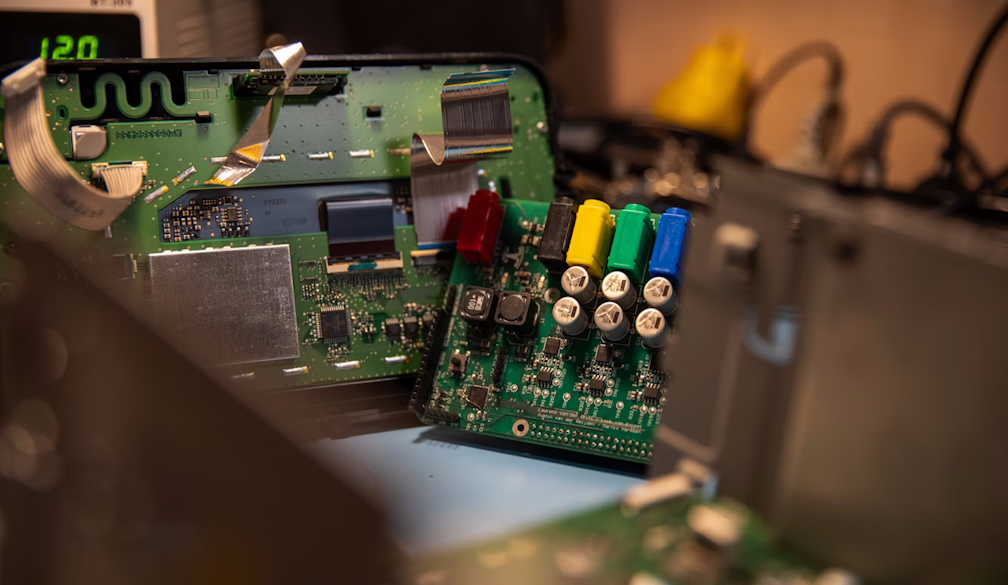

Electrical thermal imaging is a diagnostic method that uses infrared cameras to detect heat emissions from electrical components. Every object emits infrared radiation, and when electrical components overheat, it becomes visible through thermal imaging. This technology allows electricians to assess the condition of cables, fuses, breakers, connectors, and other electrical elements without any physical contact or dismantling.

This method is widely used in predictive maintenance. Instead of waiting for equipment to fail, businesses can monitor thermal patterns and intervene early. By spotting irregular heat signatures, technicians can diagnose overloaded circuits, poor connections, or faulty components—often long before they manifest as electrical fires or system failures.

Why Electrical Thermal Imaging Matters

Electrical faults are among the leading causes of fires in commercial and industrial settings. Overheating wires and poor insulation can remain unnoticed until it’s too late. With electrical thermal imaging, these threats can be identified in real-time and resolved quickly.

This technology is particularly useful in environments with complex or aging electrical infrastructure. Regular thermal scans ensure that all components are functioning within safe parameters. As a result, facilities benefit from improved safety, reduced risk of equipment failure, and extended asset life.

Additionally, electrical thermal imaging is cost-effective. It prevents unexpected breakdowns, which can be expensive in terms of both repairs and lost productivity. Businesses can schedule maintenance proactively rather than reacting to emergencies.

The Role of Switchboard Thermal Imaging

A switchboard is the central distribution point for electrical circuits in any building. It houses breakers, fuses, and connections that manage power flow across various zones. As such, it is also a common source of electrical issues. Switchboard thermal imaging focuses specifically on scanning the switchboard for signs of overheating or abnormal energy discharge.

Switchboards are prone to high resistance connections, loose wiring, and overloads—all of which can generate excessive heat. Unlike physical inspections that may miss internal faults, switchboard thermal imaging captures thermal patterns and highlights components that are running hotter than they should.

By identifying hotspots early, electricians can make targeted repairs, avoiding potential blackouts, damage to connected equipment, or even electrical fires. This process is particularly important in facilities with high electrical loads, such as factories, hospitals, data centres, and commercial buildings.

Compliance and Insurance Benefits

Routine thermal inspections, including both electrical thermal imaging and switchboard thermal imaging, can also support compliance with safety regulations. Many insurance companies now require proof of preventative maintenance, especially in commercial and industrial buildings. A detailed thermal report can serve as documentation that systems are being monitored and maintained appropriately.

For businesses, this not only ensures a safer environment but can also result in lower insurance premiums and fewer liabilities. In some jurisdictions, regular thermal imaging assessments may even be a requirement under workplace health and safety laws.

When and How Often Should Thermal Imaging Be Done?

The frequency of electrical thermal imaging depends on the size and nature of the building or facility. For most commercial properties, an annual thermal inspection is generally sufficient. High-risk environments, such as manufacturing plants or data centres, may benefit from more frequent checks—every six months or even quarterly.

Ideally, these inspections should be conducted during normal operations when systems are under typical load. This provides the most accurate representation of performance and helps detect issues that may only arise during peak usage.

Qualified electricians or thermography specialists should conduct the scans, as interpreting thermal images requires training and experience. A reliable technician will not only identify anomalies but also recommend actionable solutions.

Investing in Peace of Mind

Preventative maintenance is always more affordable and less disruptive than emergency repairs. With electrical thermal imaging, you’re gaining a window into the hidden workings of your electrical infrastructure. You can spot issues like unbalanced loads, deteriorating wires, and overloaded components—before they result in expensive or dangerous failures.

Similarly, switchboard thermal imaging gives targeted insights into the heart of your power distribution. It ensures your switchboard is operating efficiently and safely, protecting your building and everyone in it.

Conclusion: A Smart Step for Every Property Owner

In a world where downtime can be costly and safety is paramount, electrical thermal imaging and switchboard thermal imaging offer an invaluable advantage. They are fast, non-intrusive, and highly effective tools that support safer, more reliable electrical systems.

Whether you manage a commercial building, oversee an industrial site, or simply want peace of mind in your home, investing in regular thermal imaging checks is a practical decision. It's a simple, proactive way to reduce risk, extend the lifespan of your electrical assets, and meet safety and insurance requirements with confidence.