A Beginner's Guide to Sterile Packaging for Medical Components

- Written by NewsServices.com

Medical packaging serves a variety of purposes. But do you know its most significant function? It is to safeguard a medical or pharmaceutical product. It is as important as the quality mv circuit breakers to prevent your medical lab from short circuits.

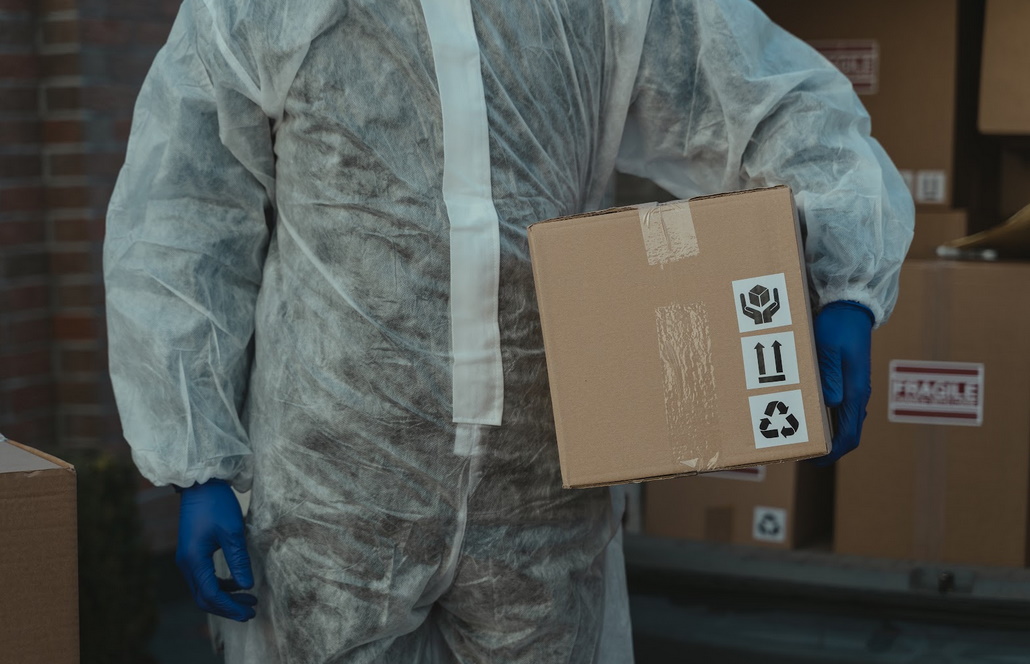

Due to the fact that medical products have unique criteria and frequently require sterilization before packaging, medical packaging is designed to meet the highest medical standards while also protecting the product's integrity ergonomically.

Medical packaging covers an entire range of pre-formed packages. Not only this but also customized packages for specialist parts falls in the same category. This happens as a result of the broad variety of medical components. Even the most delicate medical component can be shipped in a suitably engineered box due to variations in size, breathability, dimension, stiffness, and sterility.

Sterile Packaging

The effective launch of a medical gadget relies heavily on sterile barrier packaging. The basic information covers the foundations of packaging, including an overview of materials used in healthcare packaging.

You can also learn some important aspects to consider when selecting materials, device features, the optimal sterilizing method, and much more. Testing requirements and the validation procedure are also important to learn sterile injection molding.

Sterile Medical Packaging Materials

Many medical items rely on medical polymer films. These are an important component of medical packaging, to protect them from contamination and retain their integrity. Medical polymer films also protect against light and moisture, along with other gases while inhibiting or allowing air circulation.

Medical film materials include the following:- Single films

- Laminations

- Coextruded films

Polyethylene-cellophane, polyethylene-polycarbonate, polypropylene-cellophane-polyethylene, etc. are some of the materials utilized to make laminations.

Coextruded films produce several layers concurrently, whereas laminations require individual layer manufacturing. Adhesives and coatings are sometimes replaced by coextruded films. High-density polyethylene, polypropylene, polystyrene, or polyvinyl chloride are commonly used in coextrusion films. Most coextruded films are gas-tight, allowing them to be used as sterile product packaging.

Sterile Medical Packaging Standards

Various codes exist to ensure that medical packaging is of the highest quality. The following are two of these requirements:

ISO9000: Quality Management StandardPSO9000: Pharmaceutical Packaging Materials Standard

After a package is created, it is tested and inspected to ensure that it fulfills the required standards.

Package Testing Requirements

Seal integrity (seal strength), distribution testing, material integrity (bubble leak), and package aging are all part of the package validation testing for medical devices. These are described in ISO 11607.

The lead time for package aging is the longest. Aging tests can take anywhere from one to six months. This usually depends on the intended shelf life, therefore it's crucial to consider this into the timeframe during the planning stage.

Before any testing, the final package assembly must be conditioned as it would be in real life. In simple words, the product should be sterilized before it undergoes packaging testing.

Different Types of Sterile Medical Packaging

A variety of structural configurations are used to package medical components. The following is a list of some of the most frequent medical packages.

Individual-wrap packages

Single-use applications, such as syringes, benefit from this form of packaging. Blister packs are frequently used to provide additional assistance.

Multi-compartment trays

Multi-compartment trays have been used to package implants, sutures, and other sensitive surgical products. They are often made of more hard material.

Water-soluble packaging

This type of packaging dissolves in water. This property makes it ideal for products that require the addition of water to perform their purpose. For example certain nutritional supplements.

Blister packaging

Blister packaging protects a package's contents from contamination and is commonly used to store individual capsules within a larger carton. Blister packs can have either a peelable layer or a push-through lidding to extract the contents of the box, depending on the film type employed.

Pouches

These can be used to store a variety of irregularly shaped items. To suit sterilizing requirements, they can also be made from a variety of materials.

Cartons

Cartons, which are made of fiberboard, are ideal for goods that can be stored at room temperature within a standard, made-to-size boxed construction. Individual cartons are frequently used to package over-the-counter medicine. For example, basic capsule tablets. White-lined chipboard to basic folding box boards are all possibilities.

Wrapping Up

Too often, especially when corporations are developing their flagship medical product, the commodity takes center stage. Consider sterile packaging as a supporting character that occasionally steals the show. Because aseptic packaging entails several designs and testing considerations, it is ideal to begin developing it as early as feasible in the product development process.

Also, to avoid costly mistakes, collaborate with experienced packaging professionals who are familiar with quality plastic mold maker and know proper testing techniques. Their techniques must comply with the regulating agency's regulations, the Food and Drug Administration (FDA).